Vision Systems

SPM 3D vision and i-Weld technologies encompass the latest in robotic vision guided technology. Robots are able to adapt on-the-fly to process variations typically encountered in the production of large plastic parts. Product quality is improved dramatically.

SPM 3D vision technology encompasses the latest in robotic vision guided technology.

Robots are able to adapt on-the-fly to process variations that would have traditionally produced scrap using

common methods.

A definite industry first and a step forward in robotic plastic welding, cutting, and assembly applications.

As Made Part

Scanned Image

Computed Image

Reduce your finishing operations with SPM's i-Weld technology. With no boring operations required, i-Weld is an excellent solution for meeting PZEV requirements.

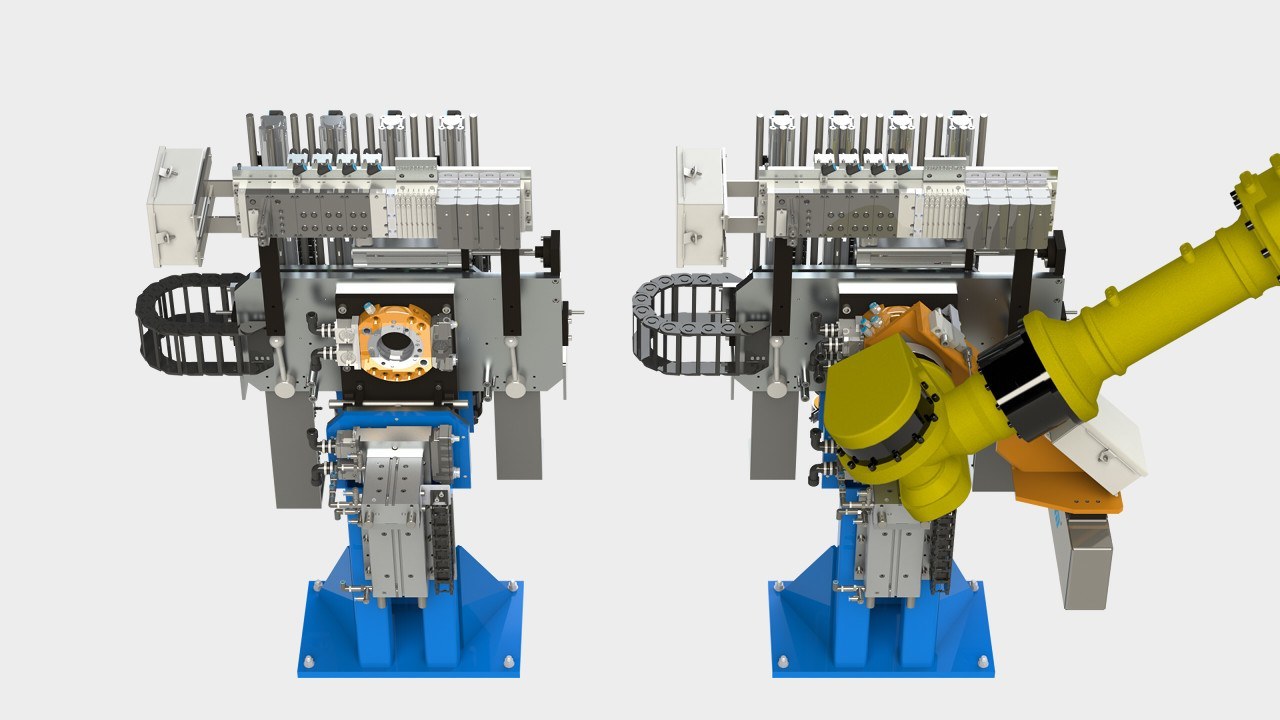

Servo boring tools used in robotic applications can accommodate weld pads with and without blow needle openings. Slugs are positively retained and sensed both on the tool and in the chute to guarantee 100% slug removal.

When equipped with the SPM 3D vision system, the robot is able to adapt to process variations and ensure the bored opening is always precisely located.

Robots are able to dynamically change the boring head on-the-fly during the processing cycle.

Tool storage stands are provided to store up multiple tools that accommodate different bore diameters and weld pad configurations.