Flexible Finishing Machines

Fuel tank finishing machines designed and built by SPM are cost-effective and represent the latest state of the art technologies. SPM machines have proven to increase productivity, reduce scrap, and lower overall costs.

Standard ICV welders provided by SPM have proven to increase hermetic weld quality, reduce cycle time, and improve overall efficiencies.

See how SPM's standard ICV welder with 3D vision technology can optimize your plastic welding processes

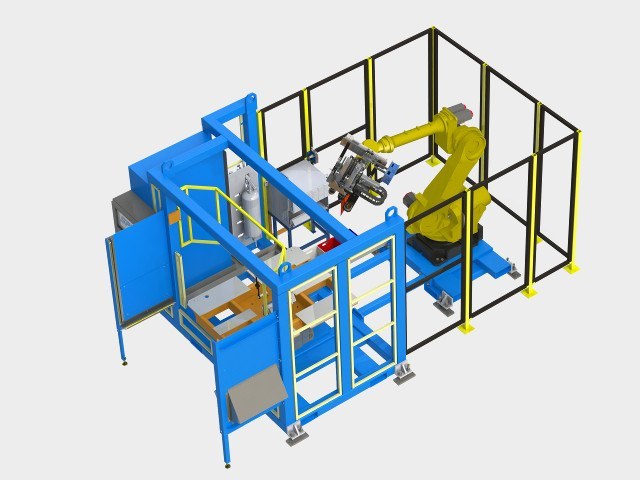

Dedicated Finishing Machines

SPM dedicated machines are designed to perform various processing operations, such as boring, cutting, machining, welding and assembly. Although each machine is designed based on individual requirements, proven subassemblies minimize delivery time, cost and risk, as well as improve overall quality and performance.

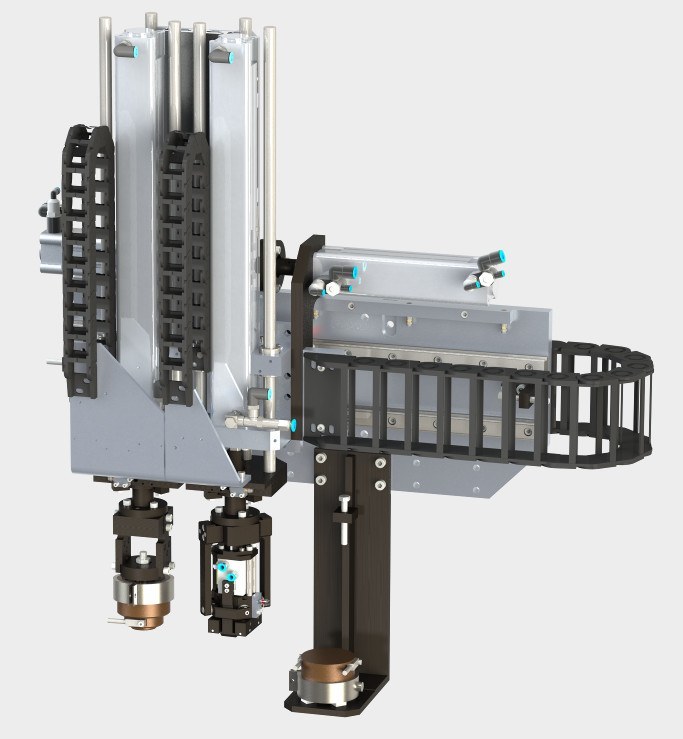

SPM standard fusion units are available for both open and closed loop applications to suit hermetic and non-hermetic welding applications.

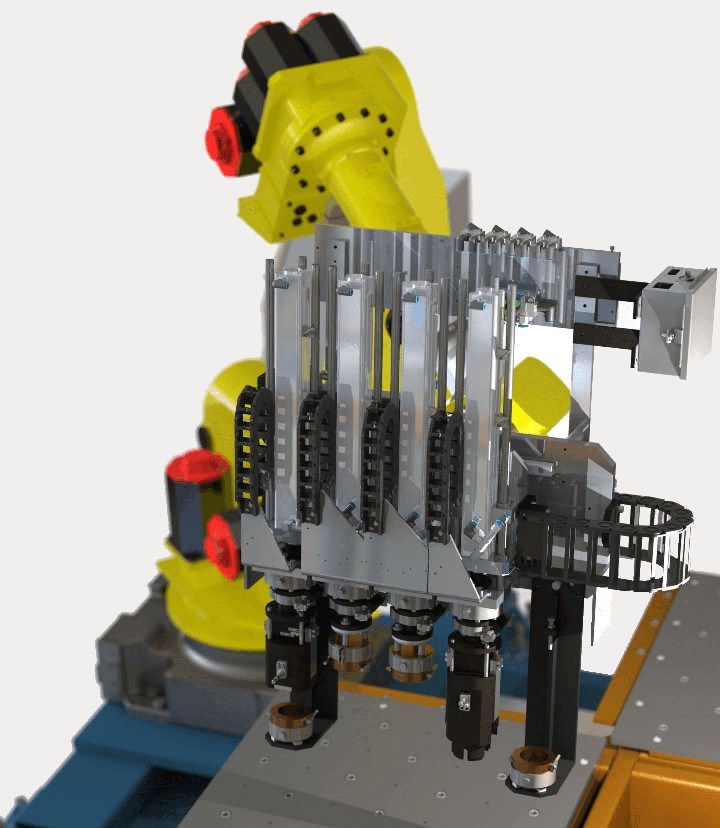

Dual actuator units precisely control forces on both the component and tank throughout the welding process.

SPM's latest servo boring technologies allow on-the-fly tool changes between different hole diameters and weld pad configurations.

This greatly reduces overall capital investment as only one boring tool is required for multiple boring operations.