Prototype and Short Run Development

SPM offers complete support and fast track prototyping and short runs for plastics joining and assembly. With our broad capabilities, we can offer hot plate, infrared and vibration welding processes along with various plastic cutting and assembly options.

With our in-house vibration welder, we have the ability to produce welded assemblies to meet your requirements as well as validate production tooling and define optimal process parameters for your production process.

Prototype Welder Specifications:

Our design team can develop custom prototype tooling with production intent to help save you development costs when pursuing alternate production processes.

New procedures and production methods can be fully tested and validated at SPM prior to making an investment in a flexible or dedicated production system.

Combined with our robotic protoyping capabilities, we are equipped to provide you with short production runs for many applications such as:Design Development

We want to help you from the beginning stages of your product design and development. We will work closely with your design team to develop the most cost-effective joining method that will yield the highest strength weld joints in your production process.

There are many important design considerations which can affect the look and strength of the welded areas in your product. Working together with SPM during the initial design and concept phase of your project will ensure that you have the strength and aesthetics you need.

+

When you need to know: Can we weld it?

With a wide range of plastics available, it can be difficult to be sure your welded product will fulfill all of your requirements. Don't worry, we are here to help. We can help you choose which materials to use, and verify that your final material selection can be welded with the performance you expect.

Plastics joining tooling and equipment designed and built by SPM include a comprehensive report outlining overall weld quality and consistency prior to delivery to your production floor.

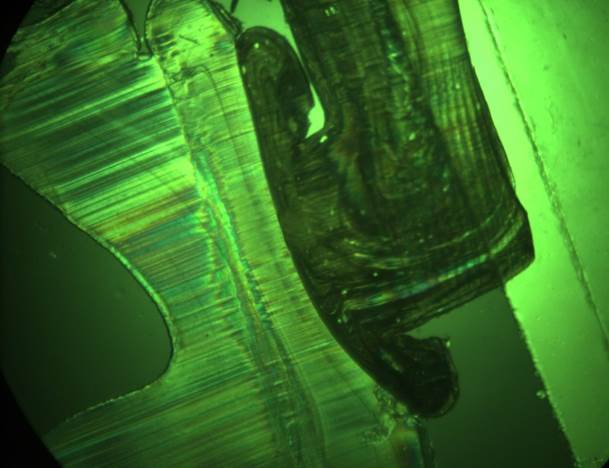

Microscopic weld joint analysis using microtome sections of welded samples is one tool which allows SPM to verify weld quality.