SPM’s standard welding range are a great solution for your plastics joining needs – high speed, robust, modular, highly accurate, and easy to use. Our expert staff will provide component and joint design recommendations, material capability studies, and prototype sample welding. Detailed weld joint analysis, thermal imaging reports, and microtome reports are provided from our in-house lab.

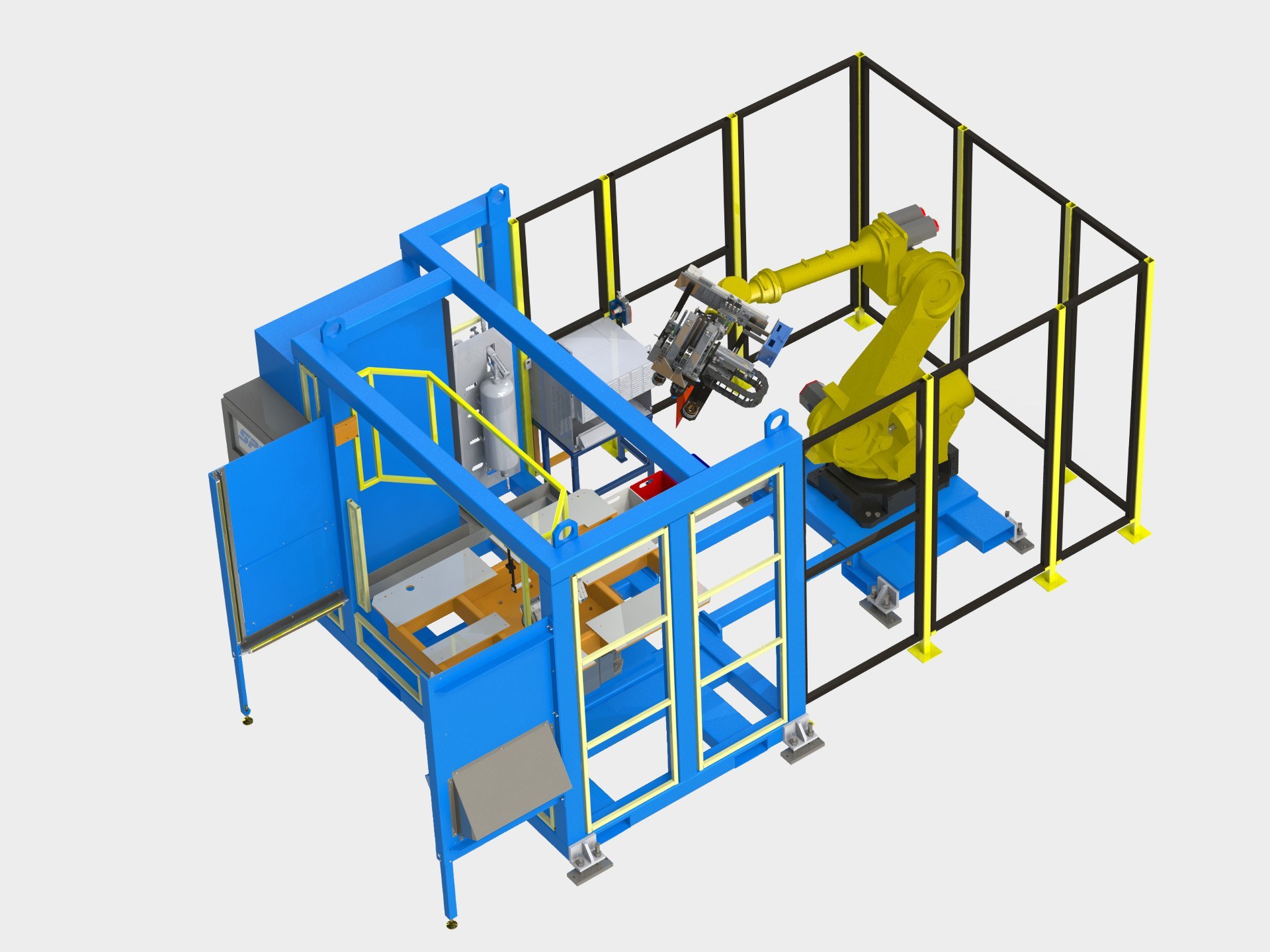

Hybrid machine versions are now available allowing our customers increased flexibility, lower overall capital investments, and reduced overall floor space requirements. A great solution for shorter production requirements and lower volume programs. With tool change-over times of less than 15 minutes, SPM Hybrid machine variants are able to process both infrared and hot plate tool sets. Combined with the optional extended front modules, SPM hybrid technology offers our customers total flexibility for plastics joining applications.

Modular and compact design allows for flexibility for multiple tooling sets and part configurations.

LED Machine lighting for work and maintenance areas, tooling area access doors, & 10" Color touch screen HMI with user friendly, easy to follow screens.

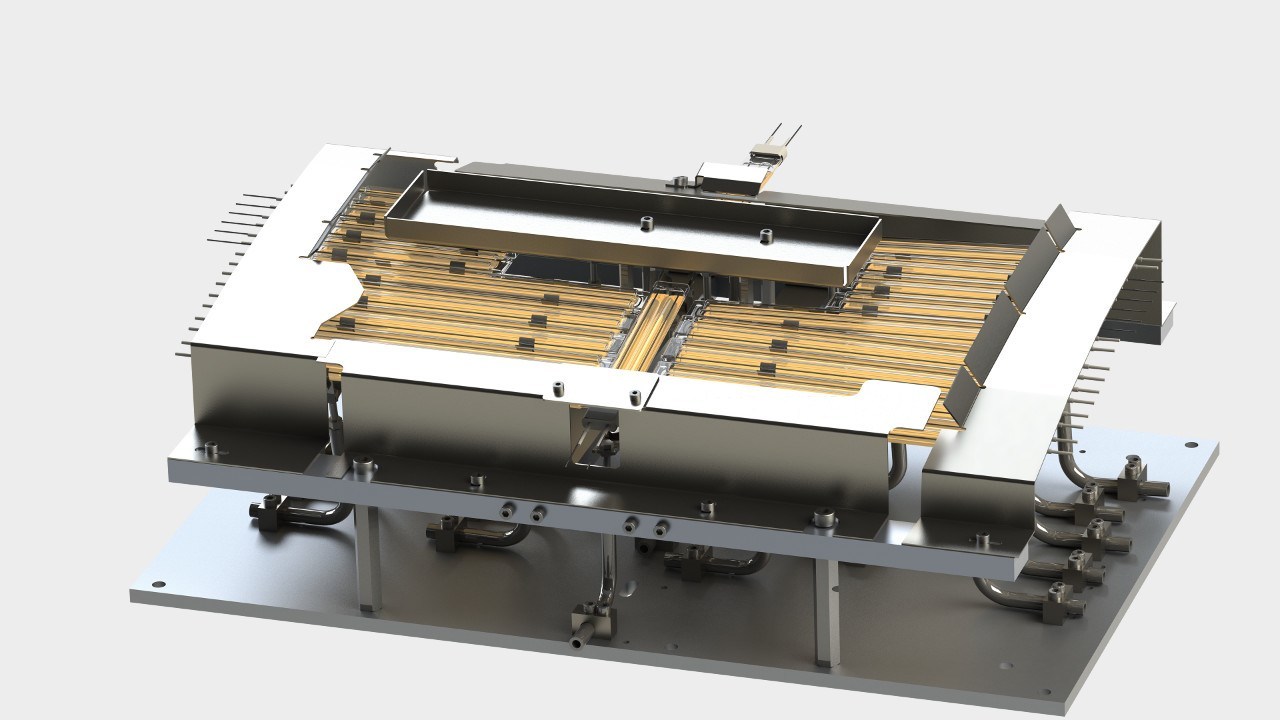

Precision linear guidance of the upper, lower, and hot plate tooling via heavy duty ball bearing guides.

Thrust loads up to 150KN. Max speed up to 500mm/sec. (minimal 'open time'). Heavy duty steel actuator construction.

SPM’s hot plate welders are your ideal solution for welding large and complicated parts. The advanced servo control of the part fixture and hot plate positions allow for precise control of melt depths resulting in high strength, high quality hermetic welds. With several standard sizes available we have the solution to fit all of your application requirements.

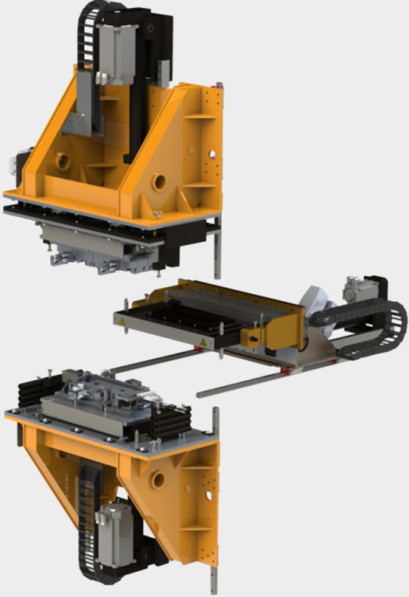

Infrared welders by SPM are your ideal solution for joining applications of reinforced high performance materials. The joining process provided by IR heating allows for greater design flexibility as complex materials are now able to be joined with high strength hermetic welds. Suitable for simple to complex geometries, and with the IR emitter's light weight and ease of installation, they are optimal for joining products with large surface areas.

Single and multi-cavity tooling specifically designed for Class A surfaces. Our expert staff will provide component and joint design recommendations, material capability studies, and prototype sample welding. Detailed weld joint analysis, thermal imaging reports, and microtome reports are provided from our in-house lab.

Precision machined part fixtures allow for a robust repeatable process. Custom tools provided by SPM are designed for:

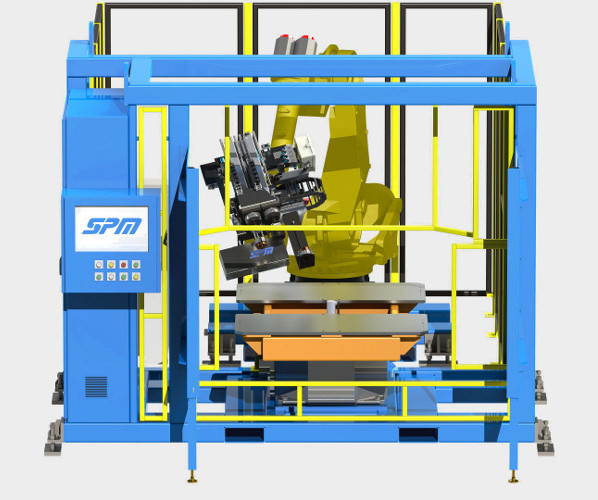

SPM’s standard ICV welder is designed to be cost effective and yet incorporate the latest state-of-art technologies. Whether you have one ICV variant or many, our standard ICV welder is an exceptional solution for your hermetic welding requirements. A flexible and robust design will provide you the highest quality hermetic seals for your automotive, recreational, and agricultural fuel tank welding applications. This flexible design also simplifies retrofits to help reduce future tooling costs.